neosim AG

High-precision lung simulation

The lung simulators from the Swiss company neosim enable realistic, hands-on training for medical professionals. They accurately replicate breathing patterns, respond autonomously to interventions, and provide instant measurable data. For this innovative project, we contribute our electronics and software expertise—from system development to quality assurance—supporting neosim in the technical implementation.

“Swiss Made is a core value for neosim. That’s why having short paths to our EMS partner is so important. But equally important are the people behind the company.”

neosim AG

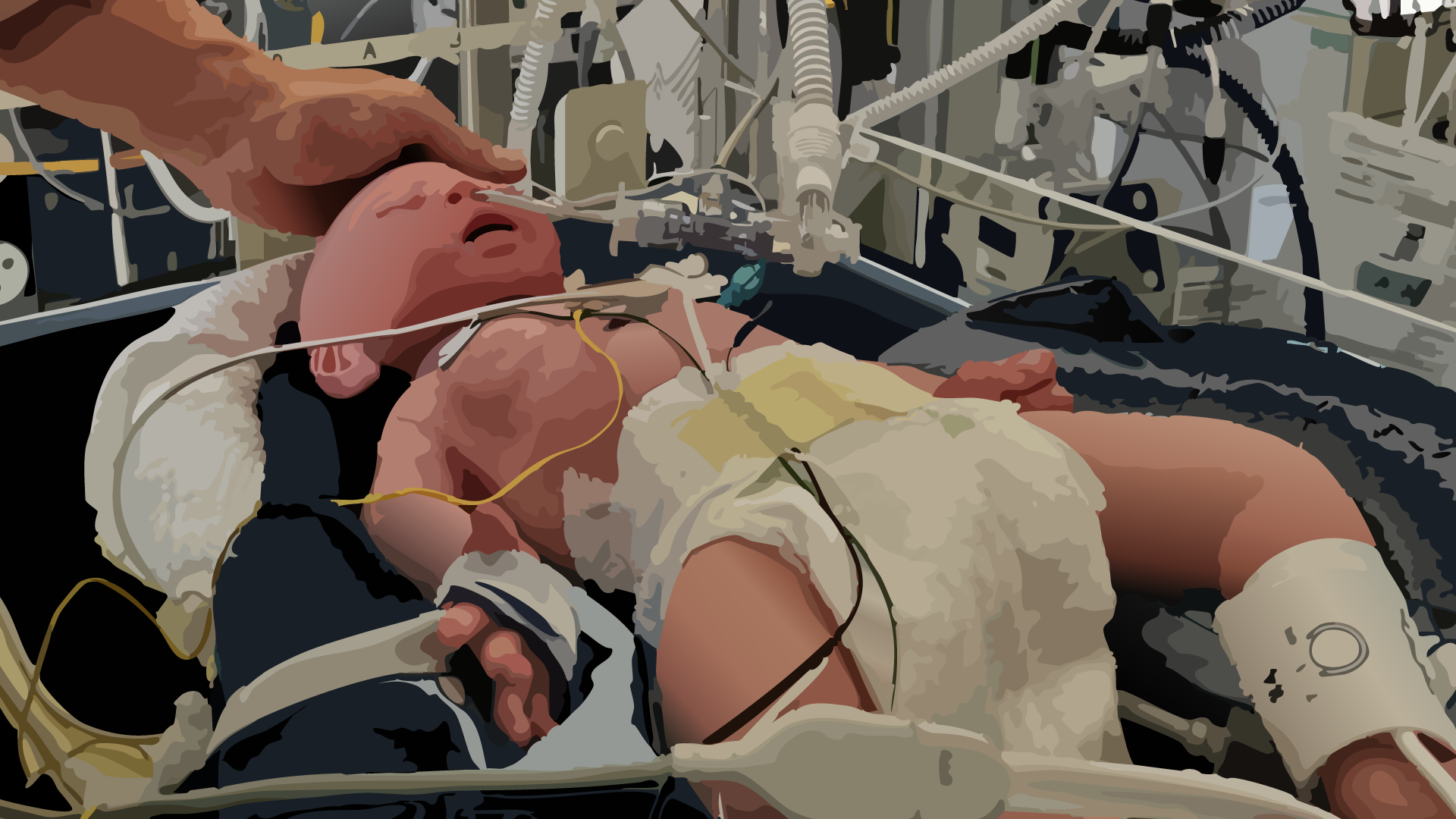

Based in Zizers, Switzerland, neosim develops respiratory simulators with autonomous physiology grounded in scientific data. The goal is to replicate real-life medical scenarios. The simulators generate lifelike breathing patterns of healthy and ill patients and respond independently to interventions. They support the training of respiratory therapists and intensive care specialists with real-time analysis through advanced monitoring methods.

2017

15 months

Swiss Made

Quality over Quantity

2017

15 months

Swiss Made

Quality over Quantity

Technically simulated lung function

Combining neosim’s expertise in lung physiology with our electronics and software know-how resulted in LuSi: a mobile, 2.5 kg infant lung simulator. LuSi produces realistic breathing patterns and enables medical professionals to practice assessing lung function and selecting ventilation methods for neonatal care.

Challenges mastered

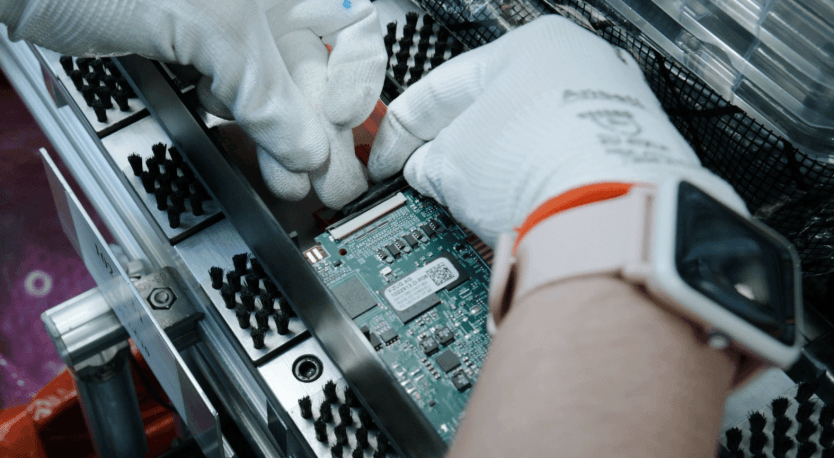

The technical implementation posed high demands on development, system integration, and quality assurance. One major challenge was mechanically replicating natural lung movement—a complex interplay of precise sensors and actuators. The project encompassed the complete development of both hardware and firmware.

Technical implementation in detail

The focus was on a custom developed control unit that combines all core functions of lung simulation. It allows real-time control, features a Bluetooth interface for connection to an external computer, and provides audio output of realistic breathing sounds. Lung movement is generated by a mechanically driven bellows under precise software control. The system includes sensors to monitor key ventilation parameters such as pressure, airflow, gas concentration, and lung volume. An energy-efficient design also enables mobile, battery-powered operation.

The interface between technology and function

A specially developed firmware framework enables easy control of sensors and actuators, as well as reliable real-time data transfer via Bluetooth. Based on this framework, neosim could implement the application firmware for simulating lung physiology independently, without deep embedded software expertise. Close collaboration produced a powerful, cost-optimized solution that meets the requirements of this innovative start-up. The product has been continuously refined over time to respond to market needs.

In conversation with Carina Barblan, Executive Assistant at neosim

Initially, the challenge was finding a reference in the complex field of neonatology. We wanted to excite doctors to determine the actual demand for lung simulators.

“Made in Switzerland” is a core quality standard that we want to convey globally. Short distances to development and production allow us to implement projects quickly and efficiently. It was essential that our partner shares Swiss roots and, like us, represents them globally.

Business always requires a clear vision. But it also needs passion and dedication from the team behind a project. That’s exactly what we found in the Variosystems development team. Plus, from a previous project, we already had complete trust in their technical expertise, which made starting the LuSi project much easier.

The collaboration enabled LuSi’s further development. With development in Buchs and rapid prototyping in Zizers, we had short paths, fast decisions, and ensured “Made in Switzerland” quality. Interacting with specialists was a real advantage for product development. Ultimately, it’s the people behind it who make the difference.

Our products must meet strict requirements for reliability, safety, and long-term performance. While electronics are the core, all components and interfaces must seamlessly work together at the same high standards. At Variosystems, we have the simulator—electronics and lung module—assembled directly, creating a fully integrated system from a single source.

The cooperation with the development team and comprehensive support throughout the project. Their deep understanding of our product enabled targeted support on all technical aspects. Our vision met real expertise—making the collaboration particularly valuable.

We use cookies on our website to enhance your user experience.

You can read more about our Cookie Policy here.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.